What is In-mold technology?

Different terms are used to describe helmets that are made by molding the outer shell and expanding foam in a single operation, with some being proprietary phrases like “co-molded” by Bell.

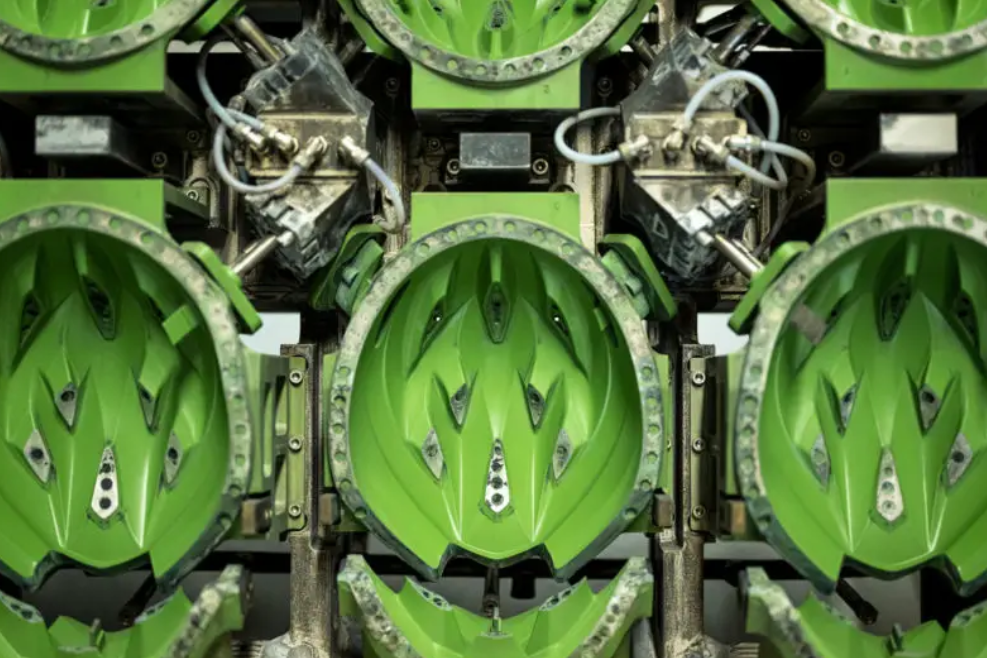

The overall process is the same, beginning with a thin plastic piece that is put into a mold, followed by adding polystyrene beads. The mold is then bolted together, with steam injected under pressure to expand the beads and complete the helmet.

This process creates a high-quality helmet with a strong bond between the EPS foam and plastic shell, providing excellent resistance to external impacts. The plastic used must be of a higher grade, due to the high heat involved. The process also allows for the addition of internal reinforcement to further strengthen the helmet.